Patterns & Tooling

Patterns & Tooling

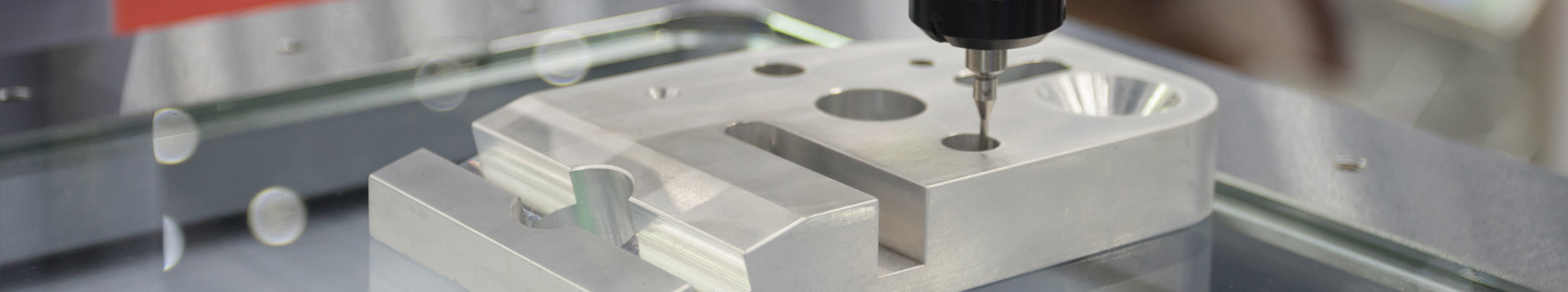

Pattern and toolmaking are essential components of the manufacturing industry, playing a crucial role in producing intricate and precisely engineered products. Smestow Pattern and Tool Specialists have earned a stellar reputation in this field due to our commitment to quality, decades of experience, and a relentless pursuit of excellence.

Pattern making is a fundamental step in the casting process, particularly in metalworking and foundry operations. It involves creating a master pattern, typically made of wood, metal, or plastic, that serves as the template or mold for producing multiple copies of a specific part through casting. This process is used in various industries, including automotive, aerospace, and marine, to manufacture complex components with exacting specifications.

The precision required in pattern making cannot be overstated. Even the tiniest imperfection can lead to costly defects and production delays. Smestow Pattern and Tool Specialists excel in this art, primarily due to our highly skilled craftsmen and engineers who have dedicated their careers to honing their pattern-making expertise. Our engineers blend traditional craftsmanship with modern technology, ensuring that every pattern they produce meets the most stringent of quality standards. One of the key reasons Smestow stands out in the pattern making industry is the close working relationship between our customers and our experienced team, who are well-versed in the time-honoured techniques of pattern making.

Precision tools are essential for shaping, cutting, and forming various materials to create the final product. Smestow Pattern and Tool Specialists have distinguished themselves in the field of toolmaking by leveraging their extensive experience and commitment to precision. Smestow’s tool specialists are adept at designing and crafting tools that optimise efficiency and quality in manufacturing processes. Whether it’s dies for stamping automotive parts or molds for intricate aerospace components, Smestow’s expertise ensures that these tools meet or exceed industry standards. Their adaptability extends to progressive dies, injection molds, and custom tooling solutions, making them a trusted partner for businesses across diverse sectors.

Smestow Pattern and Tool Specialists’ excellence in customer service can be attributed to several key factors that set them apart in the manufacturing industry. Firstly, their deep commitment to understanding their clients’ unique needs is at the core of their exceptional customer service. They take the time to engage in meaningful conversations, actively listening to their clients’ requirements and challenges. This client-centric approach allows them to provide tailored solutions that precisely address each customer’s specific demands.

Secondly, Smestow’s dedication to transparency and communication ensures that their clients are always well-informed. They keep customers updated throughout the project lifecycle, providing progress reports, timelines, and any necessary adjustments promptly and clearly. This open dialogue fosters trust and confidence in their services. Furthermore, Smestow’s responsiveness is a hallmark of their customer service excellence. They recognise that in manufacturing, time is often of the essence. Therefore, they prioritise rapid responses to inquiries, quick turnaround times, and a readiness to address unexpected challenges.